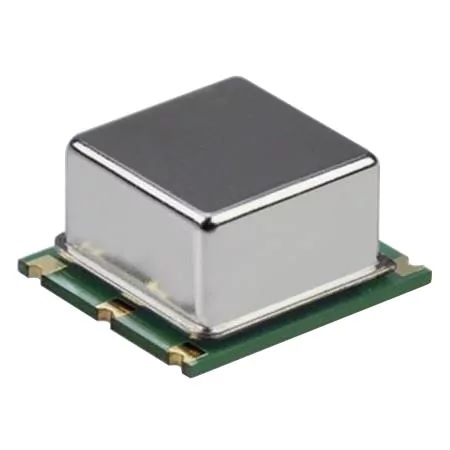

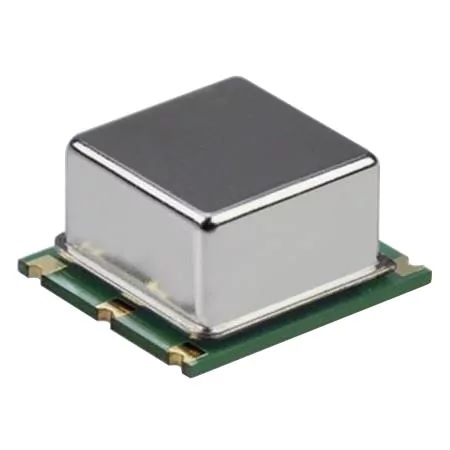

When you have a project that requires the best of the best in frequency stability, look no further than oven controlled crystal oscillators (OCXOs) from ECS Inc. These high-quality OCXO products boast exceptional stability over a wide range of temperatures, improved aging performance, lower warm-up times, higher operating temperatures, better phase noise specifications and less G-sensitivity. Uses for OCXOs include radio transmitters, cell towers, military communications equipment and other applications that necessitate sound clarity and low phase noise.

| Part Number | Support Docs | Type | Package Size | Supply Voltage | Output | Frequency | Stability | Operating Temperature | |

|---|---|---|---|---|---|---|---|---|---|

| ECOC-7050 | Datasheet Support Docs | OCXO | 7.0mm x 5.0mm | 3.3V | CMOS | 10 MHz ~ 50 MHz | ±50ppb | -40°C ~ 85°C, -30°C ~ 85°C, -20°C ~ 70°C |

| ECOC-9775 | Datasheet Support Docs | OCXO | 9.5mm x 7.3mm | 3.3V | LVCMOS | 10 MHz ~ 48 MHz | ±20ppb | -40°C ~ 85°C |

| ECOC-2522 C | Datasheet Support Docs | OCXO | 25.40mm x 22.00mm | 3.3V, 5.0V | CMOS | 2 MHz ~ 100 MHz | ±5ppb, ±10ppb, ±30ppb | -40°C ~ 85°C, 0°C ~ 50°C, -20°C ~ 70°C |

| ECOC-2522 S | Datasheet Support Docs | OCXO | 25.40mm x 22.00mm | 3.3V, 5.0V | Sine Wave | 2 MHz ~ 100 MHz | ±5ppb, ±10ppb, ±30ppb | -40°C ~ 85°C, 0°C ~ 50°C, -20°C ~ 70°C |

Oven controlled crystal oscillators, or OCXOs, feature a stress-compensated (SC) cut, high Q crystal. They use an internal thermistor to maintain the quartz crystal and oscillator circuits at a constant temperature. Having a stable environment prevents the oscillator from experiencing frequency drift, and results in a lower rate of energy loss. OCXOs provide a highly stable, clean timing source for telecommunication design, cellular base stations, data communication systems, instrumentation design, testing and measurement equipment and other applications where the highest frequency stability is required.

While all OCXO products offer superior performance, finding the oscillator that fits your specific design needs is paramount. There are several factors to consider when selecting an OCXO for a project. These considerations are largely based on the structure of the oscillator, and include:

The Thermistor

Similar to a TCXO, OCXOs have a thermistor, or a temperature sensor, that can sense the ambient temperature of the circuitry. It could be compared to a thermostat in a house. Choosing a unit with a high-quality thermistor will make a world of difference in the functionality of your application.

The Comparator Circuit

In an OCXO, the comparator circuit is used to control the amount of power generated within the heat source. When the thermistor senses ambient temperature fluctuations, it will slightly alter the resistance value, which triggers the comparator circuit to action. To compensate for this deviation, the comparator circuit will adjust the power being generated to restore the thermistor back to its original operating resistance, and bring the crystal and circuit temperature back to the set point temperature. The set point temperature is the specified temperature of operation, and is adjusted by a pre-selected resistor during the component production process. The temperature controller circuit of a typical OCXO will hold the set point temperature within ±1°C or less, but the exact metric here will be something to consider for your specific application.

The Crystal Cut

Of course, the crystal itself plays a huge role in any oscillator and OCXOs are no different. Because the cut of the crystal influences its stability, there are a couple different types of cuts: AT cut and stress compensated, or SC, cut. As mentioned above, ECS Inc. uses SC cut crystals due to their superiority over AT cut crystals in most applications. An SC cut crystal has a double rotation which overcomes the stresses that can present with AT cuts.

Get Help with Custom Electronic Component Solutions to Fit Your Design

Get in touch with a sales representative if you need more information about OCXOs or have questions about a specific requirement in your application design. Contact the ECS engineering team at engineering@ecsxtal.com for assistance with products, board respins and any additional questions. Learn more about our products and their applications by exploring our online resource library.