Get to Know the Facts About These Electronic Components’ Key Features

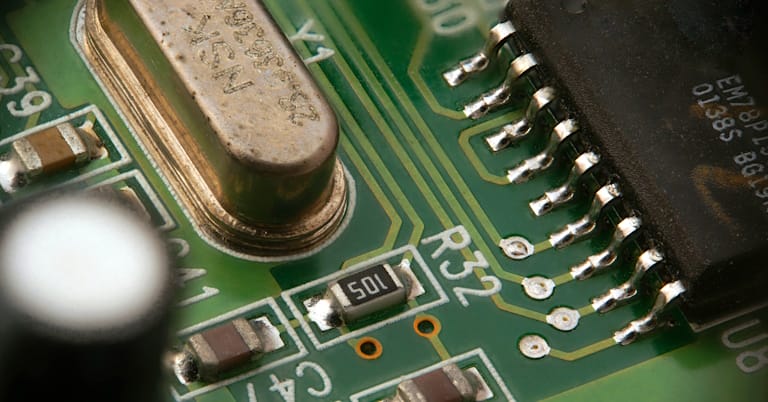

Electronics have relied on quartz crystal oscillators as a frequency solution from the late 19th century onward. Originally used for broadcasting and military applications, the use cases for quartz crystal oscillators have expanded exponentially. As the technology market grows and expands, the demand for operational efficiency and improved performance from semiconductor components also increases.

Quartz crystal oscillators are deployed in nearly every imaginable environment. However, not every environment is hospitable to a strong, stable, clean frequency. Fortunately, engineers today have built upon quartz-based clocking technology to ensure that, no matter where you need them, quartz oscillators can deliver their key functions.

Compensation or control is the general term used to describe how oscillators function when they have been modified to adjust to a changing environment, so that applications which rely on frequency operate as expected. ECS Inc. provides a variety of solutions to meet the needs of industries that require quartz crystal oscillators.

These solutions include:

- VCXOs (voltage controlled crystal oscillators)

- TCXOs (temperature compensated crystal oscillators)

- OCXOs (oven controlled crystal oscillators)

All of these crystal oscillators provide a control or compensation feature, so internal or device-to-device clocking operates as expected.

The VCXO: Compensation for Frequency Drift from Device to Device

While VCXOs tend to get grouped with TCXOs and OCXOs, this is largely because of the abbreviation of its name. However, VCXOs do not concern stability over temperature. Additionally, a VCXO is positioned in a circuit board that intends to receive a frequency from another device or application, whereas a TCXO or OCXO is integrated into a circuit board, so the outgoing (or internal) frequency signal is stable.

As an application sends data across a frequency, the signal invariably runs into obstacles that shift the frequency slightly higher or lower. Without control on the receiving side, that data will not be received as expected. A VCXO applies voltage to shift the frequency of the oscillator up or down to match the altered frequency from the transmission side.

Five fast facts about how a VCXO delivers temperature compensation for further stability:

- Voltage is controlled in a VCXO with a varactor diode, much like a TCXO.

- “Pullability” is an important consideration when choosing a VCXO. Pullability is the extent to which you can alter your oscillator’s frequency through external voltage control.

- If your application requires a higher pullability, this is achievable, although a lower pullability provides better stability and lower phase noise. Your selection depends on your application’s needs, as not all applications demand the cleanest frequency.

- VCXOs are available in three output types: HCMOS, LVDS and LVPECL.

When selecting a VCXO, ensure you have calculated the APR (absolute pulling range) for your electronic component. The APR is the deviation from the crystal’s resonant frequency that your crystal can achieve when the highest and lowest levels of voltage control are used.

ECS Inc.’s Temperature Solutions: TCXOs and OCXOs

Quartz crystal oscillators are subject to temperature fluctuation. When a crystal oscillator experiences temperature changes outside its operable range, the resonant frequency will vary.

However, quartz crystal oscillators are still required to properly function in applications that experience temperature changes. There are many variables that could contribute to temperature changes in a circuit design including environmental factors or design configuration. Some devices are deployed outdoors or in locales with harsh environments. Some devices can experience a wide temperature fluctuation between operation and dormancy, such as a car’s engine that heats up while running, then may lie dormant outdoors for the night.

Therefore, if an engineer desires a stable frequency, compensation or control is a must. The best solutions for stability over temperature are TCXOs and OCXOs. These electronic components allow a core oscillator to execute its key timing functions without the detrimental effects of temperature affecting its performance.

Five fast facts about how a TCXO delivers temperature compensation for further stability:

- Although the OCXO is proactive in nature, the TCXO is reactive. TCXOs are often positioned “downstream” from the OCXO in the larger circuitry network to provide additional stability as a second wave of defense against frequency drift.

- A TCXO relies on four key electronic components to protect the core oscillator from drift: a controlling signal generator, pulling network, voltage regulator and output buffer.

- A controlling signal generator senses the temperature of the circuitry and supplies voltage, much like a thermistor and comparator circuit in an OCXO. The pulling network adjusts the oscillator’s temperature back to the desired range with help from a capacitor called a varactor diode.

- The voltage regulator and output buffer serve as safeguards against internal voltage fluctuations and external load. This ensures that the TCXOs voltage is delivered precisely for temperature compensation, without additional obstacles that could hinder stability.

- The TCXO delivers further stability in parts per million, offering additional support for the primary performance quality of an OCXO.

Five fast facts about how an OCXO delivers its temperature control solution to achieve stability:

- OCXOs are proactive, meaning that the optimal temperature range for frequency stability is maintained inside the component.

- This component contains two key parts to control the temperature range: a thermistor and a comparator circuit.

- The thermistor registers the temperature of the circuitry, much like a home thermostat. The comparator circuit adjusts the oscillator’s voltage to bring the temperature back to its predetermined point.

- The quartz crystal’s cut for placement in an oscillator also ensures frequency stability. ECS Inc. applies a stress compensated (SC) cut, which delivers superior performance characteristics in comparison to alternative cutting methods.

- A highly effective and sensitive component, OCXOs can deliver frequency stability in parts per billion, depending on the desired temperature range for your application.

Trust VCXOs, TCXOs and OCXOs for Superior Frequency Stability

No matter what application you are designing for, you need to ensure that your circuitry includes compensation and control for frequency drift due to temperature and other factors. VCXOs, TCXOs and OCXOs designed by ECS Inc. provide the technology you need to deliver the high-performing engineering you are known for.

If you need help during the selection or build process, never hesitate to contact engineering support. ECS Inc. can help you every step of the way to achieve success, including aiding you in your search to find the electronic components that best suit your design’s requirements. When you are ready to order ECS Inc. products, connect with a sales representative or authorized distributor near you. You can also contact ECS Inc. online at any time for questions or any additional information you may need.

VCXOs vs TCXOs vs OCXOs was last modified: December 11th, 2023 by