Written by David Meaney, Vice President of Global Technical Sales and Marketing

When the discussion of oscillators comes up, the same question will arise. What is the choice for performance in critical applications, MEMS (Micro-Electro-Mechanical Systems) or quartz-based oscillators? MEMS-based oscillators have been available on the market since 2005. In the last 15+ years, a handful of companies have developed MEMS-based oscillators. Today, only a few remain and the leading MEMS-based oscillator manufacturer accounts for around 1% of the total timing market. Many frequency control manufacturers private label from both companies, with the exception of ECS who does not see any value in the practice.

When selecting the oscillator for your electronic devices or communications equipment, some of the timing considerations you need to think about are: system performance, system clocking, signal quality and reference signal sources. These are the critical parameters that will decide the performance level of your product.

You may have seen another video from a MEMS manufacturer comparing MEMS oscillators to stand alone quartz crystals. It is proven that any oscillator be it quartz, SAW, ceramic, or MEMS will always outperform any standalone resonator. So, a comparison of an oscillator to a crystal is not a true test of the oscillator’s performance. In this side by side comparison, we will look at and directly compare a quartz-based oscillator with a MEMS oscillator.

1) Quartz-Based Oscillators

2) MEMS-Based Oscillators

Structures and Characteristics:

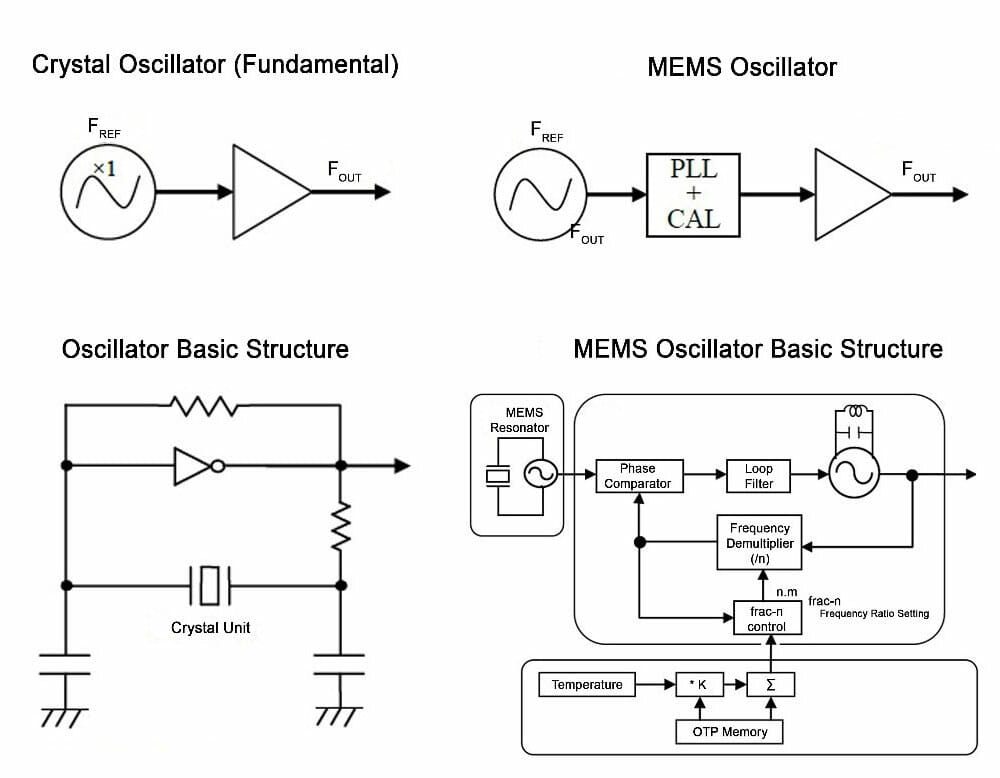

A crystal oscillator uses a quartz crystal reference and a simple oscillator circuit.

A MEMS oscillator uses a silicon resonator as the oscillating source and requires a PLL circuit to correct the frequency for manufacturing tolerances and temperature coefficient.

As these basic structures indicate, crystal oscillators are high quality clocks that are simply built. In contrast, MEMS oscillators have a complex structure consisting of a MEMS resonator, a fractional-n PLL and temperature compensation network. They also require manufacturing calibration to operate correctly.

The basic structure of these oscillators is shown in Figure 1.

ECS Inc International tested and measured quartz-based oscillators and MEMS-based oscillators and compared them for six parameters which are critical for the design of communications, networking, industrial, and consumer electronic devices. ECS Inc also offers a summary of compiled data:

- Power Consumption: How much current is consumed?

- Oscillator Start Up: How quickly does the oscillator start after power is applied?

- Jitter and Phase Noise: What is the noise performance (a critical factor in communications equipment?

- Frequency vs. Temperature Characteristics: How stable is the frequency with respect to changes in temperature?

- Frequency Stability: How stable is the frequency when measured at 25°C?

- ibration Sensitivity: Performance under adverse conditions

- Reliability: Mean time between failures. Also known as (MTBF)

- Summary: Overall performance review

1. Power Consumption

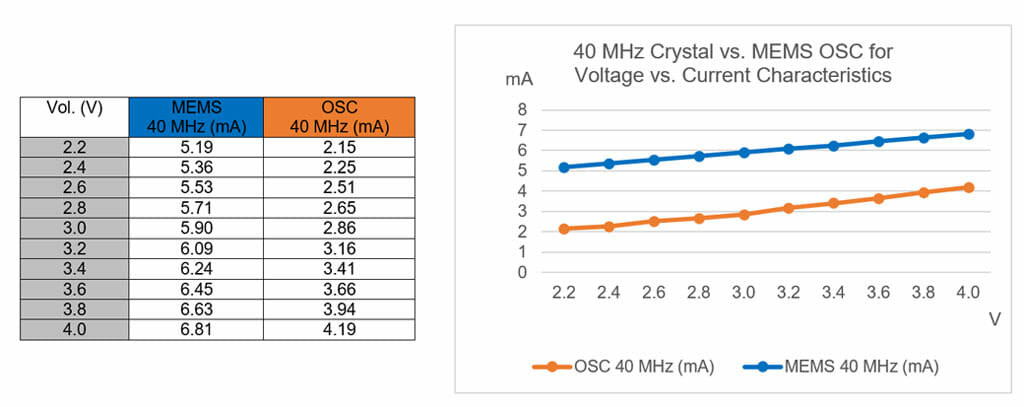

Quartz-based oscillators have much lower power consumption because they have the advantage of a fundamental or harmonic oscillation and a simple circuit structure.

By contrast, MEMS-based oscillators consume more power because they have more circuitry. The PLL and LCVCO raise the total power consumption. As a result, the MEMS oscillator draws 6.09 mA and the standard quartz oscillator draws about 3.16 mA, that’s two times more current needed by the MEMS to only achieve comparable jitter and phase noise levels to the quartz oscillator.

Figure 2: Power Consumption Measurements for MEMS and Quartz Oscillators 40 MHz.

2. Oscillator Start-Up Characteristics

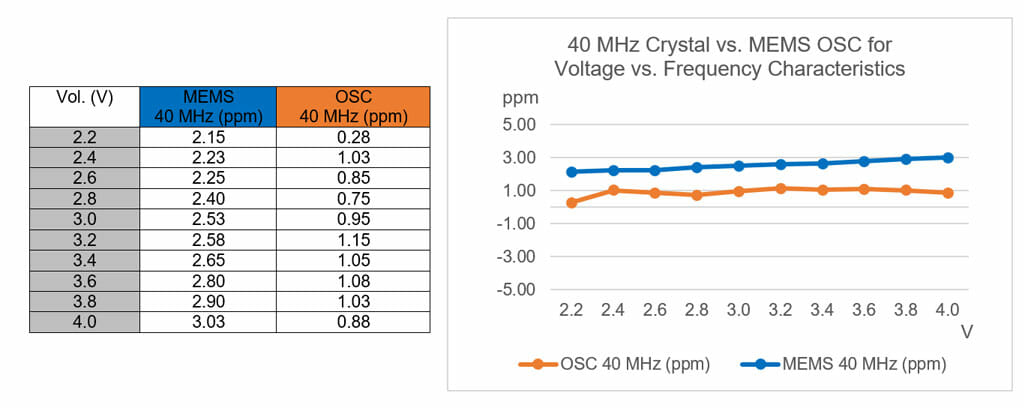

Comparing the stability of an oscillator as they are powered up, the quartz oscillator achieves 1 ppm accuracy almost as soon as power comes on. While the MEMS oscillator struggles to get to 2 ppm accuracy. After startup, the quartz oscillator is stable, but as you can see the MEMS oscillator is exhibiting frequency tremors as the PLL and LVCO try to stabilize. As shown in Figure 3 below.

Today, more than ever, fast startup is important. Whether it’s in a consumer product, automation, or a military application, today’s electronics need to be powered off and on to increase battery life or bring a system online. Clocks to be up and running steady when needed. Using an oscillator with faster startup and stabilization, like the quartz oscillator from ECS Inc., allows shorter wakeup cycles and longer battery life.

Figure 3: Oscillator Start-Up Characteristics 40 MHz

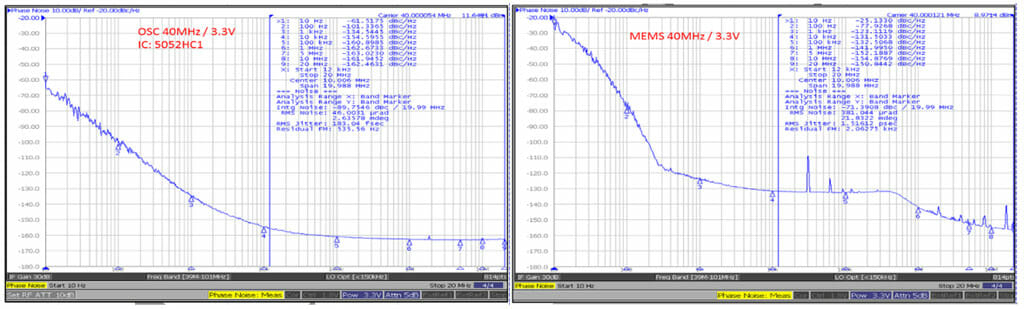

3. Jitter and Phase Noise

A) Jitter

We choose off the shelf comparably priced oscillators. One with a MEMS-based resonator and one with a quartz- based resonator. When measuring the jitter of the MEMS oscillator from 12 kHz to 20 MHz, we get 1.5 pS rms jitter measured. When testing the quartz-based crystal oscillator across the SONET bandwidth of 12 kHz to 20 MHz we achieve a 0.18 pS rms jitter. This is nearly eight times better than the MEMS oscillator. The ECS part was selected for the comparison because it is a “standard oscillator” used in many applications and manufactured in large volume. See Figure 4 below.

B) Phase Noise

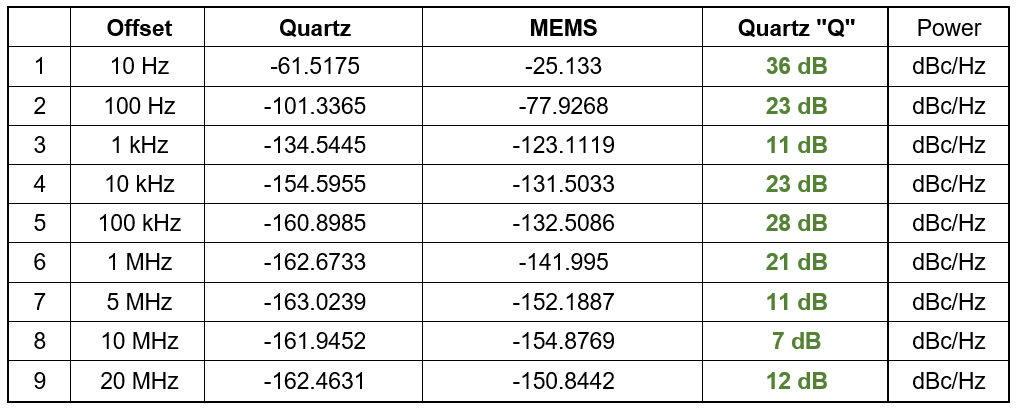

Laboratory measurements also demonstrate that the quartz oscillators have much better phase noise than the MEMS oscillators.

MEMS oscillators have higher phase noise for low offsets because the silicon resonator has poor “Q” or Quality factor as compared to quartz. At 10 Hz, the quartz oscillator has 36 dB better phase noise than the MEMS oscillator. Phase noise at low offsets is critical for wireless communications and can cause some errors in optical communications. MEMS oscillators also have higher phase noise for high offsets (12 kHz to 20 MHz) because they use a low-Q LC oscillator for the PLL circuit.

Figure 4: Phase Noise Performance of Quartz vs. MEMS

MEMS Oscillators have spurs caused by the fractional-n divider. These spurs occur in-band and cause deterministic jitter (DJ), which degrades system bit error performance. Spur-induced DJ must be considered as part of the jitter budget for all types of circuits: wired, optical, and wireless. Quartz oscillators using fundamental crystals do not have such spurs.

Figure 5: Measured Jitter and Phase Noise for the Compared Oscillators.

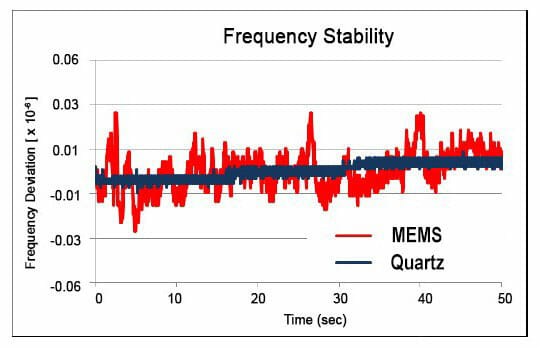

4. Frequency Stability

Measurements of frequency stability for each oscillator are shown below in Figure 6. These results are measured at 3.3 V and 25°C for a time of 50 seconds. MEMS has frequency jumps on the order of ±600 ppb, well in excess of most wireless standards. The quartz-based oscillator shows very little movement and is by far more stable.

Figure 6: Quartz Oscillator and MEMS Oscillator Stability Plot

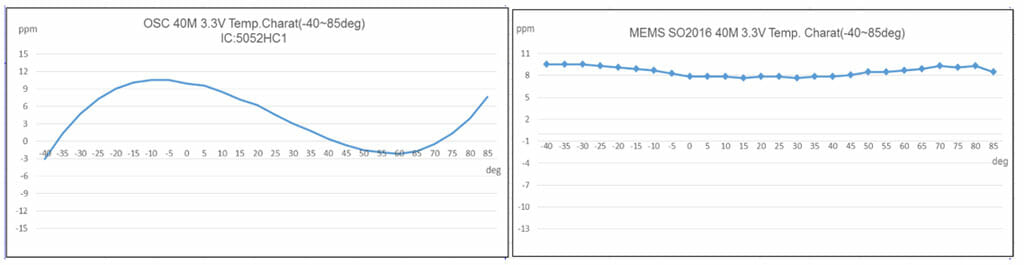

5. Frequency Over Temperature Characteristics

When comparing the Frequency vs. Temperature stability of quartz and MEMS. You see that the quartz-based oscillator follows the continuous cubic curve of an AT crystal and achieves ±25 ppm from -40°C ~ +85°C, which is good enough for most applications.

Looking at the MEMS plot it appears to have better frequency vs. temperature characteristics, but if you look closely you can see that the plot shows frequency jumps caused when the PLL division ratio is adjusted to compensate for changes in temperature. This causes significant Frequency jumps in order to compensate for the considerable frequency drift of the MEMS resonator (30 ppm/°C or 3750 ppm -40°C ~ +85°C)

Quartz is much more stable over temperature than MEMS and offers high “Q” performance. The quartz-based oscillator does not need to employ temperature compensation to maintain stabilities as low as ±10 ppm over the required temperature range. If better stabilities are required, you can add temperature compensation to a quartz oscillator and get stabilities as low as 0.5 ppm over temperature.

Figure 7: Frequency vs. Temperature 40 MHz

MEMS technology also claims to have other improvements over quartz technology, but when you look closely in these areas you find out that you are more than likely giving up much more than you are getting. In this world, nothing is free.

6. Vibration Sensitivity

MEMS claim performance gain in vibration sensitivity. If we look at the data this is quickly debunked. The typical measured range is specified from the less than one levels up to 2 kHz. Vibration density levels are reduced greatly above 2 kHz. We measure phase jitter integration in the range of 12 kHz to 20 MHz. This range is significantly higher than the maximum vibration level that any customer would specify. With improved quartz geometry’s, higher frequency blanks, and better manufacturing process, quartz manufacturers have greatly improved the vibrational sensitivity to those of MEMS.Vibration sensitivity units of measure are parts per billion per g of vibration (ppb/g)A) MEMS vibration sensitivity ranges from 0.01 ppb/g ~ 1 ppb/g.

B) Quartz vibration sensitivity ranges from 0.1 ppb/g ~ 1 ppb/g

7. Reliability (MTBF)

Mean Time Between Failure (MTBF) for MEMS is stated at 130,000 years, as compared to a quartz device stated at 30,000 years. On the surface a 4:1 ratio of improvement seems like a significant talking point until you consider most products are designed with a less than five-year life cycle. Typically, long life designs are in the ten to fifteen-year life cycle, with a very small group needing as much as twenty years. If you compare the jitter, phase noise, and temperature performance tradeoffs you lose when comparing MEMS versus quartz, you are giving up a tremendous amount of performance today so your product might last for 130,000 years. For reference: Humans have been around for 200,000 years. Civilization for a mere 6,000 years. I think we can all agree that 30,000 years is enough.

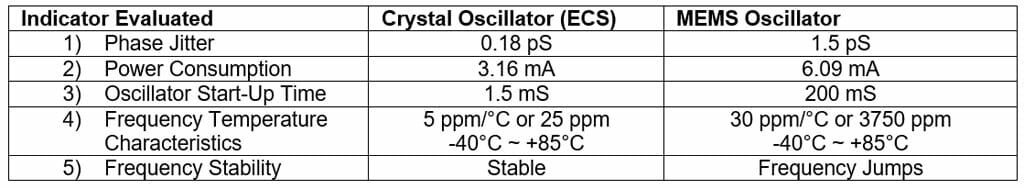

8. Summary

A summary of evaluation results for indicators 1 ~ 5 shown below.

For more technical resources, please reference our library of technical guides, educational video library on frequency control and product information, our reference design library or our current product catalog.

Please contact us if you need additional information or have a specific requirement in your application.

ECS Inc. International

15351 West 109th Street

Lenexa, KS 66219

Tel: 913-782-7787

Toll Free: 1-800-237-1041

Fax: 913-782-6991