Written by David Meaney, Vice President of Global Technical Sales and Marketing at ECS Inc. International

Introduction to Quartz Crystal Tuning Forks

Quartz crystal tuning forks, or watch crystals, are one of the oldest quartz crystal designs. Originally used for time keeping in watches and clocks, tuning forks are now also used in modern electronics, like computers, as real time clocks (RTC). There are hundreds of millions of these uniquely shaped quartz crystals being manufactured by global suppliers each year. Tuning fork crystals are available in a variety of sizes to meet the needs of designs with trends pointing to smaller surface mount crystal packages every year.

Quartz crystals were named tuning forks because the design of the crystal plate, also known as a wafer or blank, resembled the shape of a musical tuning fork. The working principle being similar; The two tangs will vibrate at a certain frequency. The frequency of the tuning fork is defined by the mass and dimension of the tuning fork tangs including the length, width, and height.

Tuning Fork Crystal Background

As the name suggests, quartz crystals are made from quartz. Traditionally, quartz is a naturally occurring hard mineral but most of today’s quartz is synthetically grown in autoclaves which provides higher standard purity than natural quartz. Quartz is used because of when mechanical pressure and tension are applied becomes piezoelectric and will create an electrical charge. This pressure causes mechanical vibrations that we call frequencies.

The quartz will need to be cut at precise angles to initiate a particular vibration mode and ensure the piezoelectric effect is working. One of the most common crystal designs is the AT Cut crystal. The frequency of AT Cut crystals is determined by the thickness of the crystal. For example: the thinner the crystal, the higher the frequency. The vibrating mass of the crystal will directly determine whether a parallel or series resonant crystal is needed for a crystal oscillator circuit design. For more information on choosing series or parallel resonant crystals, visit our additional technical guide here.

Tuning Fork Crystal Frequencies and Operating Principles

There are four common crystal mechanical vibration modes: flexure, extensional, facial shear, and thickness shear. Quartz crystal tuning forks will operate in flexure mode characterized by the tangs vibrating on the horizontal plan independently but in phase. Flexure mode crystals operate primarily at a low frequency range below 1 MHz. While overtone modes are possible, tuning fork crystals are primarily used as fundamental frequencies.

The most common quartz crystal frequency is 32.768 kHz. This frequency has become common because when 32.768 kHz is divided by 2/15, there is a 1 Hz signal. That 1 Hz signal will provide a one second time consistently. This provides a reliable timing system for day, date, and time occurrences. The frequency of the classic tuning fork is ultimately the result of a simple arithmetic operation and the general conditions of quartz production.

Tuning Fork Crystal Parabolic Temperature Curve

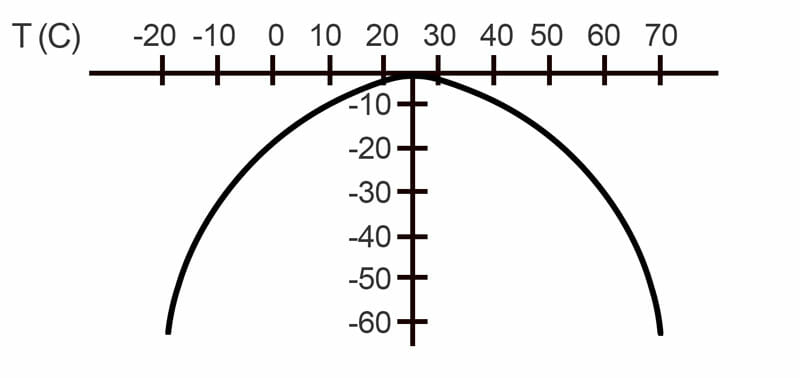

Because of their unique shape, tuning fork crystals do not provide high accuracy over a wide temperature range. Their temperature accuracy can be plotted as a parabolic curve over temperature. This accuracy is typically ±20ppm at room temperature or roughly +25°C. This is the equivalent of gaining or losing 1.7 seconds of time each day or 10.34 minutes per year. Figure 1 shows the decrease of accuracy at extreme high and extreme low temperatures. The typical accuracy at these temperatures is much worse than ±150ppm which is the equivalent to losing almost 13.0 seconds of time each day or approximately 1.3 hours per year. A common parabolic coefficient for a 32.768 kHz tuning fork crystal is 0.04 ppm/°C2.

Figure 1: Parabolic curve to determine tuning fork frequency stability

How to Determine the Temperature versus Accuracy of a Typical 32.768 kHz Tuning Fork Crystal

The frequency deviation (Δf) of a typical crystal at a specific frequency (f) and temperature (T) is:

Δf/f = k(T – To)2 + fo

Where:

- f is the nominal crystal frequency

- k is the curvature constant

- T is the temperature

- To is the turnover temperature

- fo is the frequency deviation at room temperature

An analysis of this equations reveals only three variables that control a crystal’s frequency response over temperature. These are the curvature contact, turnover temperature, and room temperature frequency deviation. The curvature constant has the most effect on the parabolic nature of the frequency deviation over temperature, but this constant has a very small deviation. Different turnover temperatures shift the deviation curve left or right and different frequency deviations at room temperature will shift the curve up or down.

Automotive Grade Tuning Fork Crystals

Automotive grade tuning fork crystals should also be taken into consideration when concerned with temperature. ECS Inc. International’s automotive grade crystals are built in IATF-16949 compliant factories and are AEC-Q200 certified. The components are PPAP supported if needed and offer special performance that is not found in standard tuning fork crystals.

Automotive grade tuning forks can be specified with standard specs such as -40°C ~ 85°C but also offer extended temperature ranges reaching +105°C and in some cases 125°C. Depending on their application, automotive grade crystals are generally subjected to extreme temperature changes; these crystals could see variations in temperature of over 100°C many times a day. The ruggedized AEC-Q200 crystals are built with more attachment points and provide excellent performance under high shock and vibration environments. For example, while people ride in cars, the active suspension is continuously adapting the drive for optimal comfort and the tire pressure monitoring system resides in the wheels ensures that the passengers can get from point A to point B. Ruggedized crystals, among other components, can be attributed to the success of your cars’ operating systems that go through so much stress.

To see ECS Inc. International’s full AEC-Q200 crystal catalog, click here.

Thru Hole Crystals

Thru hole crystals are the second most common type of tuning fork crystal to a standard surface mount crystal. Thru hole crystals are hermetically sealed so the temperature performance of a thru hole crystal will be comparable to a standard 32.768 kHz tuning fork crystal. The primary difference between the two not being in performance, but that thru hole crystals need to be hand-placed on the printed circuit board which increases manufacturing time.

To see ECS Inc. International’s full thru hole crystal catalog, click here.

For more information on ECS Inc. International’s full real time clock catalog, click here.

To see ECS Inc. International’s full product catalog, click here.

For additional video resources, click here.

Please contact us if you need additional information or have a specific requirement in your application.

ECS, Inc. International

15351 West 109th Street

Lenexa, KS 66219

Tel: 913-782-7787

Toll Free: 1-800-237-1041

Fax: 913-782-6991